Excellence Starts with Every Stitch

At Yintex Textile, we believe that premium quality is the foundation of customer trust and satisfaction. That’s why we implement a rigorous quality control system at every stage of production — from raw material sourcing to final packaging.

Our Quality Assurance Process

1. Raw Material Inspection

We source only the finest materials, such as high-grade cotton, linen, down, and microfiber. Every batch of raw materials is thoroughly inspected for purity, consistency, and durability before production begins.

- Fiber composition analysis

- Color fastness testing

- Down and feather content checking (for comforters and pillows)

2. In-Process Quality Control

During production, our QA teams monitor each stage to ensure strict adherence to specifications.

- Weaving & Knitting Monitoring: Guarantee uniform texture, weave density, and strength.

- Cutting and Sewing Checks: Precision in measurements and seam durability.

- Filling Process Inspection: Ensure even distribution of down, feather, or alternative fillings.

3. Finished Product Inspection

Before packing, every product undergoes a thorough final inspection.

Weight and fill power verification (for comforters, duvets, pillows)

Dimensional accuracy (length, width, thickness)

Stitching strength test

Surface appearance check (no stains, defects, or loose threads)

4. Packaging Inspection

Products are carefully packed to maintain their pristine condition during transit.

Customized packaging checks if applicable

Correct labeling and barcoding

Damage-free and moisture-resistant packaging

Certifications & Standards

OEKO-TEX® Standard 100 Certified

OEKO-TEX® Standard 100 is one of the world’s best-known labels for textiles tested for harmful substances. It stands for customer confidence and high product safety. Products bearing this certification have been tested by independent OEKO-TEX® partner institutes for numerous regulated and non-regulated substances that may be harmful to human health. The certification ensures that every component of the product, from threads to buttons, meets strict limit values for chemicals. Choosing OEKO-TEX® Standard 100 certified bedding means you are providing your customers with products that are safe, skin-friendly, and environmentally responsible.

OEKO-TEX® STeP Certification

OEKO-TEX® STeP (Sustainable Textile & Leather Production) is an independent certification system for brands, retail companies, and manufacturers in the textile and leather industry. STeP certification evaluates and verifies environmentally friendly production processes, social responsibility, and occupational safety throughout the supply chain. Certified facilities must meet strict criteria in areas such as chemical management, environmental performance, health and safety, social working conditions, and quality management. By choosing OEKO-TEX® STeP certified partners, you demonstrate a commitment to sustainability, transparency, and continuous improvement in your production processes.

Learn more about OEKO-TEX® STeP.

GRS (Global Recycled Standard) Certification

The Global Recycled Standard (GRS) is an international, voluntary, full product standard that sets requirements for third-party certification of recycled content, chain of custody, social and environmental practices, and chemical restrictions. The GRS is intended to meet the needs of companies looking to verify the recycled content of their products and to ensure responsible social, environmental, and chemical practices in their production. Products certified to the GRS contain verified recycled materials and are produced in facilities that meet rigorous requirements for environmental protection, worker safety, and ethical business practices.

Learn more about the Global Recycled Standard (GRS).

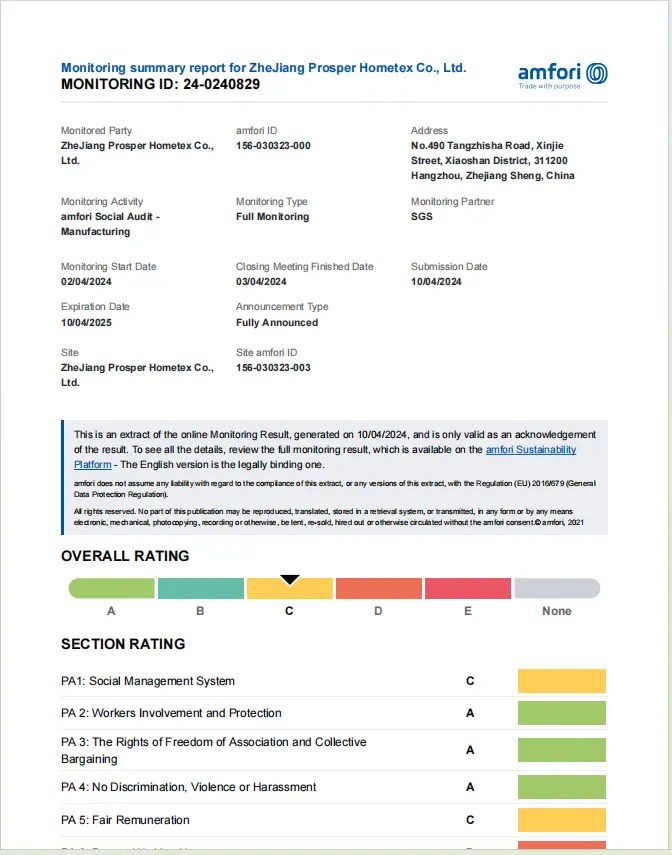

BSCI (Business Social Compliance Initiative)

The Business Social Compliance Initiative (BSCI) is a leading supply chain management system that supports companies in their efforts to improve working conditions in factories and farms worldwide. BSCI provides a common Code of Conduct and a systematic monitoring process to ensure that suppliers comply with international labor standards, including fair wages, reasonable working hours, no child labor, and safe working environments. By partnering with BSCI-certified suppliers, companies demonstrate their commitment to ethical sourcing, social responsibility, and sustainable business practices.

Learn more about the Business Social Compliance Initiative (BSCI).